What is a Positive Displacement Blower?

Shop Our Positive Displacement Blowers Here!

General Definition of a PD Blower

What is a positive displacement blower? A positive displacement blower, otherwise known as a PD blower or rotary air blower, is a type of machine that is used to move gas or air for a variety of applications. More specifically, these devices utilize positive displacement technology by trapping a certain volume of air then discharging or forcing it out against the system pressure. This air is usually forced into some type of pipe or hose to propel materials or gas to a destination.

How Does a Positive Displacement Blower Work?

If you were to dissect a PD blower you will notice that the main parts of the machine are two rotors that are joined together by gears surrounded by a blower casing. Many blowers also come with a sound absorber, air screen and other parts to improve efficiency, but when explaining how the apparatus functions we only need to focus on the rotors (often called the impeller), blower casing, inlet side and outlet side of the machine.

Once a blower is in operation both rotors will rotate at the same speed but in opposite directions in order to draw air into the blower. One rotor is called the “driving rotor” because it is run by an external power supply, while the opposite rotor is called a “driven rotor” because it is driven by gears connected to the driving rotor.

As the rotors revolve, air is pulled into the inlet side of the blower and is confined to tight areas between the rotors and the blower casing. This pocket of air is moved around the rotors and blower casing to the outlet side. Once the rotors open to the outlet side, the discharge line equalizes the pressure of the air and is forced out of the blower. The air is unable to come back due to the small amount of internal clearance between the internals of the machine. This process enables the blower to overcome line pressure hence the name positive displacement. Put differently, the volume of air does not change within the device, but is rather displaced from one end of the machine to the other.

The load resistance of the material carried in the discharge line helps to create more pressure which in turn improves the functionality of the machine. In fact, many positive displacement blowers need some sort of back pressure to generate a substantial pressure reading to propel the materials or gas handled in the system.

Types of Positive Displacement Blowers

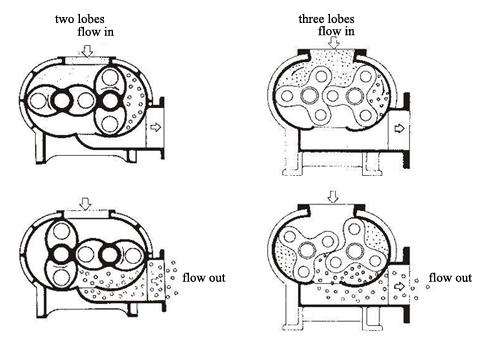

Positive displacement blowers typically utilize a straight lobe rotor design with two or three lobes and are characterized as twin lobe rotary air blowers and tri-lobe rotary air blowers. A twin lobe blower contains two figure 8 shaped lobes while a tri-lobe blower consists of three lobes shaped like a boat propeller.

Tri-lobe blowers are considered much less noisy than twin lobe blowers because the three lobe blower design allow for lower pulsation levels and reduced noise.

Common Applications of PD Blowers

As stated, PD Blowers are used in a variety of applications and industries making them a desired investment to improve processes and cut lead times. Listed below are some common applications of PD blowers:

- Chemical - Vacuum Processing & Conveying

- Dairy - Automated Milking

- Environmental Services - Sewer Cleaning & Portable

- Cement & Lime - Fluidization & Conveying

- Resin & Plastic - Processing & Conveying

- Process Gas - Gas Boosting

- Soil Remediation - Vacuum Extraction & Sparging

- Industrial - Material Vacuuming

- Milling & Baking - Blending & Conveying

- Dry Bulk Hauling - Trailer Unloading & Aeration

- Power Generation - Fly Ash Conveying & Aeration

- Pulp & Paper - Chip Conveying & Process Vacuum

- Oil & Gas - Gas Collection & Sparging

- Aquaculture – Aeration

Whatever the application, Blocker and Wallace has an extensive line of PD Blowers including Sutorbilt, DuroFlow, Drum, CycloBlower, HeliFlow, TriFlow, & Elmo Rietschle that can help to improve your processes. Each of these blower lines has unique features making them an ideal machine for a variety of industries. We also offer PD blower packages custom designed to your needs to create a stress-free process when fabricating and installing your systems. Shop now for PD blowers or contact us today to learn more about our PD blower packages!

Gardner Denver Positive Displacement Blowers for Sale

Blog Tools

- Recent Posts

-

Archives

- January 2019

- May 2017

- March 2017

- February 2017

- January 2017

- June 2016

- January 2016

- April 2016

- July 2016

- December 2016

- March 2016

- August 2015

- April 2015

- January 2015

- February 2015

- March 2015

- July 2015

- September 2015

- October 2015

- November 2015

- May 2015

- December 2014

- November 2014

- October 2014

- September 2014

- August 2014

- July 2014

- June 2014

- May 2014

- April 2014

- May 2013

-

Resources Elmo Rietschle

Elmo Rietschle - Gardner Denver vacuum pumps, side channel blowers, radial fans, rotary vane pumps, screw vacuum pumps, & liquid ring pumps.

Gardner Denver Industries

Gardner Denver Corporate website depicting industries served & brands offered.

Gardner Denver Products.com

Gardner Denver provides the highest quality and most reliable positive displacement blowers, exhausters and vacuum pumps

GD Compressors

Gardner Denver Compressor Products.

Outerbox Design

OuterBox offers Professional Web Design Services and specializes in eCommerce Website Design and Development.

Support

Search Engines