How to check the V-belt drive on your PD Blower and Vacuum Pump.

Sizing a V-belt Drive on a PD blower:

Proper sizing and Installation of your V-Belt drive is critical insure the successful operation of your PD blower. When selecting a V-belt drive, check to be sure the shaft overhung load limitation is not exceeded. You can calculate the belt pull using the formulas provided in your PD blower manual.

1.) Verify that the motor and blower pulleys are aligned and check for any offset in the plane of the pulleys.

Belt drives on PD blowers must be carefully aligned to insure proper operation. Motor and blower pulleys must be parallel to each other and in the same plane within 1/32 inch. Misaligned V-drives can cause premature bearing wear and allow the rotors to rub against the head plates and cause a reduction in the volumetric efficiency of the unit.

V-belt sheave alignment can checked by using either laser alignment tool or a straight edge. A feeler gage should be used to measure the gap in between the sheave and the straight edge.

2.) Check the belt tension

Belt tension should be carefully adjusted to the belt manufacturer’ s recommendation using a belt tension gauge. Check belt tension frequently during the first day of operation because belts may stretch and require adjustment.

WARNING: Over tightening the V-belts increases the load on the bearings which can lead to premature blower or vacuum pump failure.

3.) Check blower sheave position on the blower drive shaft

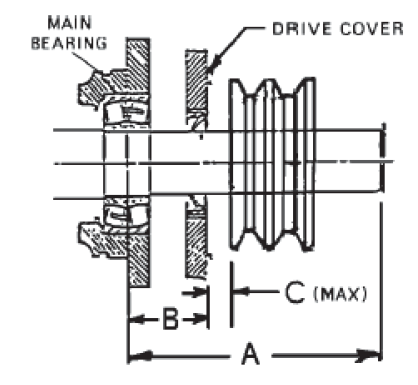

The location of the sheave or pulley on the blower shaft greatly affects the stress on the shaft and drive bearing loads. The optimum blower sheave position is as close as possible to the blower drive cover. The distance between the sheave and the face of the blower drive cover CANNOT EXCEED .038” for most blower models. Please reference distance chart and drive shaft illustration below (fig. 1).

|

Figure 1 : SHEAVE DISTANCE CHART |

|

|

Blower Model |

Dimension “ C” |

|

Sutorbilt Legend – Grease lubricated (2” – 8” gear diameters) |

.38” max |

|

Sutorbilt Legend – Dual oil Splash lubricated “ DSL” |

.25” max |

|

Sutorbilt 4500 Series |

.25” max |

|

Sutorbilt 8000 Series (10” – 22” gear diameters) |

.75” max |

|

|

|

|

DuroFlow 4500 Series |

.75” max |