Oil Lubrication Maintenance Tips

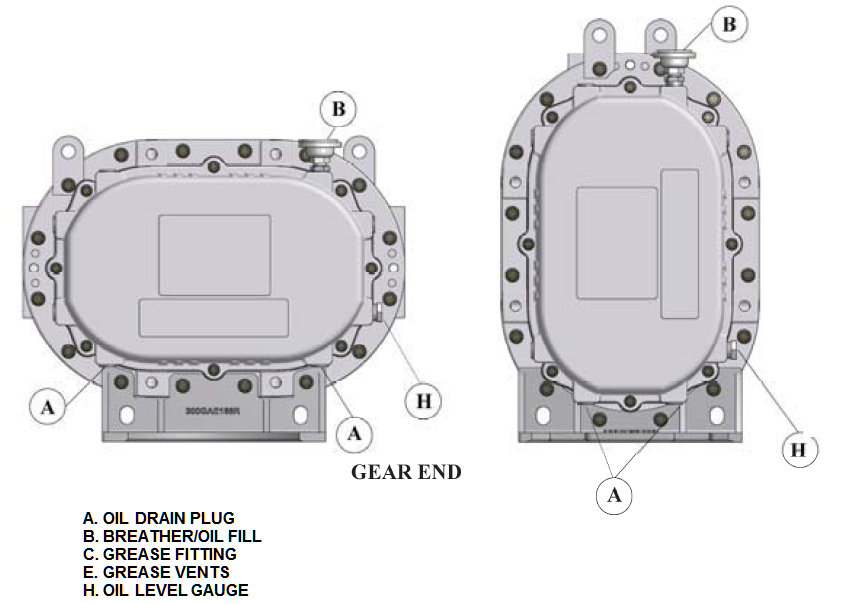

Aim to change your AEON PD synthetic blower lubricant every 500-1000 hours of operation to avoid premature wearing to bearings and gears. Additionally, if you are working in a dirty or strenuous environment, you will need to change the oil more often. We recommend that operators determine their own oil change interval periods because every operating environment is different. Oil change intervals can be determined by taking an oil sample and sending it to Blocker and Wallace for testing. We provide free oil sample analysis and oil testing on AEON PD Lubricants to aid in process of determining the oil change intervals in your PD blower. learn more about the oil sample analysis program. You can also quickly check the oil condition by looking at the level oil sight gauge located on the gear sump cover. If the Aeon PD blower oil is black or brown it needs to be changed.

What type of oil should be used in PD Blower?

We recommend using AEON PD Synthetic Oil Lubricant in your positive displacement blower or vacuum pumps. AEON PD lasts longer than most oils, a minimum of 4 times longer than typical mineral oils. The best oil type you can use in your Sutorbilt, DuroFlow, HeliFlow, Drum, TriFlow, or Truck blower is AEON PD Blower oil. If you choose not to use AEON PD Synthetic Blower Lubricant, select oil with rust and oxidation inhibitors, anti-foam additives, and an one that has an equivalent viscosity to the comparable Aeon lubricant. Do not use oil that contains EP additives.

Tips For Lubricating you PD Blower:

- The oil level should be at the middle of the sight glass when the machine is not operating. Too little oil damages the bearings and gears. Too much oil will cause overheating and can damage gears and other damage throughout the blower.

- Watch the oil level sight gauge while you’ re adding oil. Once you start to see oil in the gauge stop adding and let the oil settle to the bottom of the sump. Add additional oil as required until its mid-way in the oil level sight gauge.

- We recommend re-greasing the driven bearings when performing an oil change.

- New Blowers are shipped without oil in the sump. Do not operate before adding lubricant.

View the Oil sump capacity for your PD Blower or vacuum pumps.